News

Daikin Solution Allows Sheet Aluminum Plant in Kentucky to Run at 100 Percent Capacity

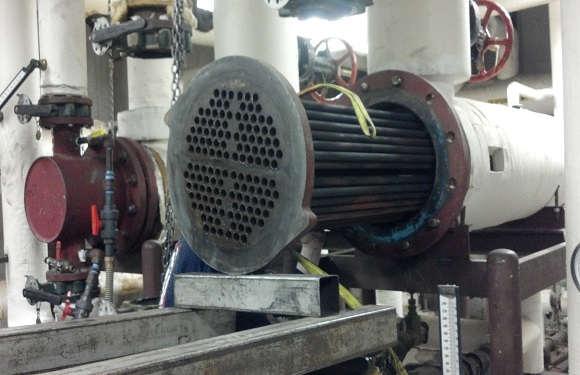

The aluminum roll material plant in Kentucky operates 24/7, processing over two billion pounds of aluminum annually, primarily for the can industry. In the production process, one of the steps/stations is the hot reversing mill. The reversing mill rolls a hot ingot of aluminum back and forth from a thickness of about 30 inches to 1 inch—whereupon it goes to the next station. The large rollers in the hot reversing mill station are driven by two 6000 HP electric, air-cooled motors. If the motors get too hot, they automatically shut down to prevent permanent damage.

Like most manufacturing plants, a forced outage in a continuous process industry like theirs is costly and time-consuming. Periodically, they were forced to shut the reversing mill motors down entirely, so they could cool down. Alternatively, management would simply slow the motors down to 70 or 80 percent of capacity to prevent overheating. Given its productivity goal of 100 percent, the aluminum plant management decided to investigate new cooling solutions for the reversing mill motors. An additional challenge was finding space for the cooling system: it would need to be compact.

The Facility

North American aluminum roll manufacturer in Kentucky that processes two billion pounds of aluminum annually, operating 24/7.

The Challenge

The challenge was to cool electric motors sufficiently to allow operation at 100% capacity, despite limited space for the cooling system.

The Solution

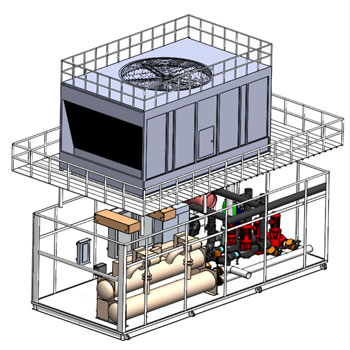

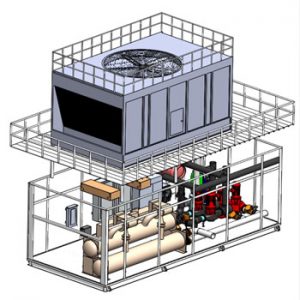

The solution, supplied by Daikin Services, was a complete turnkey modular central plant (MCP). As Dan Reekers, Cincinnati Service District Manager, described, “the MCP is a custom piece of equipment, designed and manufactured off-site by Daikin to meet the specific performance and installation requirement of the customer. Adding to the complexity, the facility had limited space available for the MCP and is located in a Seismic Design Category D. As a result, the MCP’s design had to accommodate the cooling tower being located above the central plant and required special design considerations. This fast-track solution was particularly appropriate for this customer because the facility only had a five-day installation window – a planned shutdown for infrastructure and machine maintenance. This allowed my team to receive the product and install/reassemble it on site in this relatively short amount of time.”

At the heart of the MCP is a Daikin WDC centrifugal chiller. Given the 750-ton capacity chiller utilizes two compressors with variable frequency drives, it provided cost-effective redundancy. Each compressor allows the chiller to still produce 60% of its design capacity, requiring less space than multiple chillers and improving part-load efficiency. This resulted in greatly reduced overall energy consumption, lower installed cost as compared to two separate chillers, and a central plant that is easily able to vary its cooling capacity to support changes in cooling demand.

The Outcome

The solution was completed in March of 2020, during a planned five-day outage at the aluminum roll material plant. It is working extremely well, especially given the high summer month temperatures, and the plant has realized increased productivity. Despite being recently installed, the payback projection is measurable in months instead of years. The line is working at full capacity and plant management is extremely pleased with the solution, but also the turnkey project management offered by Daikin Services. Daikin Services provides installation, testing, start-up, and after-sales support.

About Daikin Applied Americas

Daikin Applied Americas, a member of Daikin Industries, Ltd., designs and manufactures technologically advanced commercial HVAC systems for customers around the world. Customers turn to Daikin with confidence that they will experience outstanding performance, reliability and energy efficiency. Daikin Applied equipment, solutions and services are sold through a global network of dedicated sales, service, and parts offices. For more information or the name of your local Daikin Applied representative, call 800-432-1342 or visit, www.DaikinApplied.com.

About Daikin Industries Ltd.

Daikin Industries, Ltd. is a Forbes 1000 global company with 2019 revenues of over $24.3 billion and more than 70,000 employees worldwide, making it the largest HVAC manufacturer in the world. Daikin is engaged primarily in the development, manufacture, sales and aftermarket support of heating, ventilation, air conditioning and refrigeration (HVACR) equipment, refrigerants and other chemicals, as well as oil hydraulic products. Daikin was named one of the world’s most innovative companies by Forbes magazine. For more information, visit www.daikin.com.