News

Inactivate Airborne Pathogens with UV Airstream Disinfection

Contributed by UVR Resources

Like other disease outbreaks, the 2019 COVID-19, coronavirus pandemic has intensified the search for effective infection control measures. Ultraviolet Germicidal Irradiation (UVGI or UV-C) is drawing widespread attention as a formidable weapon against surface and airborne bacteria and pathogens.

Nearly eight decades of research and thousands of applications in hospitals, urgent care centers, primary and secondary schools, universities and first-responder locations have proven the efficacy of UV-C to inactivate airborne and surface-bound viruses, mycoplasma, bacteria and fungi.

Since the onset of COVID-19, UV-C has become one of the most in-demand technologies around the world. Both the U.S. Centers for Disease Control and Prevention (CDC) and ASHRAE now include UV-C as a recommended mitigation step to slow the spread of the COVID-19 virus.1

Almost overnight, UV-C systems have transformed from a HVAC efficiency option to a health and safety necessity.

Inactivating “Killing” Airborne Pathogens

Since the 1940s, many hospitals have relied upon germicidal UV-C energy to control airborne infectious diseases, but use waned with the arrival and proliferation of antibiotics.

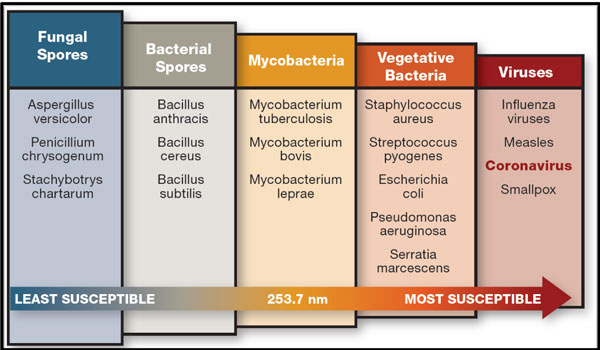

Data Source: ASHRAE Handbook-HVAC Applications Ch 62.

In the 1990s, drug-resistant “superbugs” and hospital-acquired infections sparked a renewed interest in UV-C since it can inactivate or kill virtually any microorganism, including antibiotic-resistant germs.

UV-C’s germicidal or germ-killing effects have been proven in multiple peer-reviewed studies over many decades.

The 253.7 nm electromagnetic waveform is well-absorbed by microbial DNA and RNA, making it impossible for viruses and bacteria to develop a resistance. In other words, UV-C radiation kills energetically, rather than biologically.

Through a process known as photodimerization, this electromagnetic damage destroys a cell’s nucleic acids and disrupts its DNA, preventing microorganisms from infecting and reproducing.

“UV-C systems have transformed from a HVAC efficiency option to a health and safety necessity”

There are three primary means of applying UV-C for air and HVAC surface protection against infectious agents:

- Upper-Room or Upper-Air,

- HVAC airstream disinfection, and

- HVAC coil/surface irradiation.

For the purposes of this paper, we will focus on HVAC airstream inactivation, also known as in-duct UV-C treatment.

HVAC Airstream-Disinfection Systems

UV-C air disinfection systems are installed in air-handling units, HVAC ducts, or air distribution systems to inactivate microorganisms and disinfect moving airstreams “on-the-fly.”

Designed to disinfect air as it passes through an HVAC system and before it is recirculated or exhausted, in-duct UVGI irradiates the entire cross-section of a duct with high-intensity UV-C energy.

The required UV-C dosage for an in-duct system is based on the specific target pathogen and the application parameters and can be on the order2 of 1,000 up to 10,000 μW-s/cm2.

More specifically, UV-C dose is determined by the amount of germicidal energy a pathogen absorbs over a specific length of time. Therefore, UV-C dose is a function of time and intensity.

Consider, for example, a surface-disinfection application involving cooling coils. The coil surface is stationary, so UV-C exposure or “residence” time is continuous. As a result, the UV-C intensity can be low. In the case of a moving airstream, however, exposure time is limited—a mere fraction of a second in some cases—so UV-C intensity must be greater.

Environmental Factors that Influence Pathogen Control

In addition to calculating UV-C intensity and exposure time, there are many operational and site-specific conditions to consider for an airstream disinfection system including:

- Target Pathogen and its susceptibility to UV-C. The amount of UV-C energy needed to inactivate individual bacteria, viruses, and spores have been identified through decades of research.3

- The volume and velocity of air traveling through the HVAC system, which will impact the length of exposure (residence time). A higher volume of air and/or faster-moving air requires greater intensity (more UV-C lamps) and/or a longer duct run to increase residence time.Said differently, as velocity increases beyond the typical 500 fpm, UV intensity must likewise increase. Conversely, less UV intensity is required for air velocities below 500 fpm.

- The length of the plenum/duct—the longer the plenum or duct run, the better, as residence time and, thus, dose is increased.

-

Figure 3 Temperature—because cold air reduces the output of UV-C lamps and high relative humidity (RH) affects pathogen susceptibility to UV-C, airstream-disinfection measures can be more effective on the upstream side of a coil. Although on-the-fly disinfection is accomplished downstream of coils, it typically requires greater UV-C fluence/intensity (more lamps).

- Lamps—using more or higher-output lamps will increase the total dose. Lamps with 360-degree irradiation allow more UV-C energy to saturate a plenum, increasing UV-C fluence.

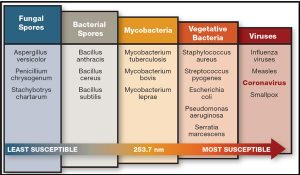

- Reflectivity of the plenum—different metals boost UV-C dose, as the germicidal wavelength remains “in play” instead of being absorbed by the surfaces. These reflectance multipliers can significantly increase UV-C fluence levels (Figure 3).

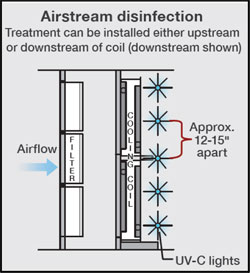

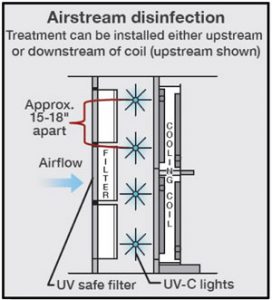

- Fixture spacing—decreasing lamp-row spacing (e.g., from the surface-irradiation standard 36-in. centerlines to 15-in. to 18-in. centerlines) increases UV-C fluence.

Pathogen Susceptibility to Germicidal UV

Although environmental considerations may increase or decrease the UV-C dose, it is best to utilize all the factors of a specific application in a predictive-modeling formula to design an effective airborne disinfection strategy.

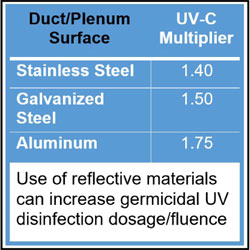

In Figure 2, we can calculate the amount of time a pathogen is exposed to UV energy to determine the total exposure time and removal rate.

Bacteria and viruses vary in susceptibility to UV energy, with environmental organisms, fungal spores, and mycobacteria being relatively harder to kill than more rapidly replicating and non-environmental microbes and most bacteria. But even fungi are killed effectively with high-dose UV.4 For example, studies have demonstrated that viruses are more susceptible to UV-C inactivation than typical bacteria (Figure 1).5

It is important to note that UV-C operates by line-of-sight; it kills only what it can see (e.g. the inside of a closed drawer cannot be disinfected unless the drawer is exposed to the UV energy).

Lamp Placement

When designing a germicidal-UV disinfection system, engineers should consider the location within the AHU and its impact on performance.

The application of UV-C for coil irradiation/surface cleaning applications has become more popular over the past 25 years.

Lamps are typically installed downstream of the cooling coil to address pathogen growth due to the presence of coil condensation and wet drain pans – both can serve as microbial breeding grounds.

Today, many building engineers are converting their existing UV installations into airborne disinfection applications by simply installing additional UV-C lamps to inactivate airborne viruses. Others are installing new systems downstream of the cooling coil to obtain the benefit of airborne inactivation and coil/drain pan irradiation (Figure 4).

Installation of lamps upstream of a coil (Figure 5) can leverage higher lamp output with the warmer environment (70°F avg. upstream vs. 55°F avg. downstream) to enhance airstream disinfection. For upstream applications, engineers need to specify UV-C safe air filters to prevent degradation by the germicidal energy.

Conclusion

Although germicidal UV-C systems have been used successfully for more than 80 years, their application in infection control settings has waxed and waned.

Given the increased focus on the prevention of airborne transmission of infectious diseases, facility professionals can utilize germicidal ultraviolet technologies to greatly reduce concentrations of pathogens in a highly reliable and cost-effective fashion.

In fact, ASHRAE’s position document on airborne infectious diseases (reaffirmed February 2020) identifies germicidal UV-C energy as a proven method of controlling airborne infections, alongside ventilation and particle filtration.

Germicidal UV has been extensively peer-reviewed and is recognized in two ASHRAE Handbook Chapters (2019 HVAC Applications and 2017 Fundamentals (Ch. 62) and two ASHRAE test standards (ANSI/ ASHRAE 185.1 “Method of Testing UV-C Lights for Use in Air-Handling Units or Air Ducts to Inactivate Airborne Microorganisms” and 185.2 “Method of Testing Ultraviolet Lamps for Use in HVAC&R Units or Air Ducts to Inactivate Microorganisms on Irradiated Surfaces.” The technology is also reviewed in three ASHRAE Position Documents (Airborne Infectious Diseases; Infectious Aerosols; Filtration and Air Cleaning).

What’s more, germicidal UV has been recognized in the CDC’s guidance for office buildings,6 health-care facilities7, 8 and dental settings.9

Recent guidance from ASHRAE, the CDC and published technical articles in HVAC trades provide building engineers and facility staff with the resources needed to size, select, install, operate, and maintain UV airstream disinfection systems.

Learn more about UVR Resources, the leader in UV-C disinfection and HVAC efficiency, at UVResources.com.

Footnotes:

1 CDC. (2020). COVID-19 employer information for office buildings. Centers for Disease Control and Prevention. Retrieved from cdc.gov/coronavirus/2019-ncov/community/office-buildings.html

2 ASHRAE. (2019). ASHRAE handbook—HVAC applications, Chapter 62 Ultraviolet Air and Surface Treatment. Atlanta: ASHRAE. Retrieved from https://www.ashrae.org/file%20library/technical%20resources/covid-19/si_a19_ch62uvairandsurfacetreatment.pdf

3 Kowalski W. (2009) UV Rate Constants. In: Ultraviolet Germicidal Irradiation Handbook. Springer, Berlin, Heidelberg https://link.springer.com/book/10.1007/978-3-642-01999-9

4 Illuminating Engineering Society. May 5, 2020. IES CR-2-20-V1, Germicidal Ultraviolet (GUV) – Frequently Asked Questions. https://media.ies.org/docs/standards/IES%20CR-2-20-V1a-20200507.pdf

5 IBID, 3

6 IBID, 1

7 Sehulster, L., & Chinn, R.Y.W. (2003). Guidelines for environmental infection control in health-care facilities. Centers for Disease Control and Prevention and Healthcare Infection Control Practices Advisory Committee. Retrieved from https://www.cdc.gov/mmwr/preview/mmwrhtml/rr5210a1.htm

8 DHHS. (2009). Environmental control for tuberculosis: Basic upper-room ultraviolet germicidal irradiation guidelines for healthcare settings. Department of Health and Human Services. Retrieved from https://www.cdc.gov/niosh/docs/2009-105/pdfs/2009-105.pdf?id=10.26616/NIOSHPUB2009105

9 CDC. (2020). Guidance for dental settings. Centers for Disease Control and Prevention. Retrieved from https://www.cdc.gov/coronavirus/2019-ncov/hcp/dental-settings.html#EngineeringControls