Georgia News

Mingledorff’s Tech Service Tips: Evacuation and Dehydration Methods

By Bubba Moore, Technical Services Manager, Southeast District

Evacuation techniques are meant to remove air and moisture trapped in a refrigeration system. Air takes up space in the refrigeration system and causes reduced heat transfer plus erratic operations. On the other hand, moisture in the refrigerant system can freeze-up and block refrigerant flow. Moisture also combines with the oil and refrigerant to form acids and sludge, which can cause system damage or failure.

There are a couple of evacuation methods that are used. They are the deep vacuum method and the triple vacuum method.

The Deep Vacuum Method

The deep vacuum method relies on evacuation to dehydrate moisture from the refrigeration system. A deep vacuum is any vacuum of 500 microns or less. As the vacuum reduces pressure, the boiling point of water is also reduced. During this time of the deep vacuum the ambient temperature surrounding the system needs to be higher than the boiling point of the moisture in the system. For example, at a vacuum of 5,000 microns, liquid water will boil off anywhere in the refrigerant system where the temperature is 35 degrees or higher.

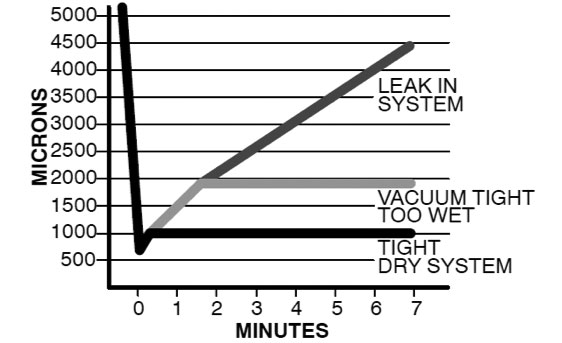

How do you know the system has been adequately evacuated? First, the system needs to be vacuumed to 500 microns or below, then it is isolated from the vacuum pump. Now the vacuum gauge needs to be monitored to see if there are any changes in the level of vacuum in the system. If the vacuum gauge shows a pressure rise and the pressure continues to rise without leveling off, a leak exists somewhere and needs to be located and repaired.

If the vacuum gauge shows a pressure rise and levels off between1,000 and 2,000 microns within seven minutes, the system is leak free but still too wet. A constant reading on the vacuum gauge of 500 to a 1,000 microns within seven minutes indicates a tight leak free dry system.

The Triple Vacuum Method

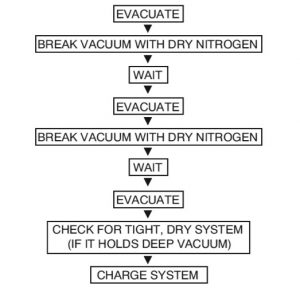

The triple evacuation method can take about three hours when performed as recommended. The system is first evacuated to 5,000 microns during the first and second evacuations. Between the evacuations, the system is pressurized with dry nitrogen to about 10 psig and allowed to sit for an hour so the nitrogen can absorb the moisture. For the third and last evacuation, a deep vacuum of 500 microns is preformed and the system is monitored in the same manner described for the deep vacuum method.

The deep vacuum and triple vacuum methods are both used frequently to evacuate and dehydrate refrigeration systems. The deep vacuum method is normally used when new equipment is installed or the refrigeration system was opened for a repair. The triple vacuum method is usually done and recommended, if the system is especially wet or after contaminants are found in the refrigerant system.

These evacuation procedures help protect and can extend the life of a system.