Air Movement

New ECO Heat Exchanger for Systemair’s Geniox Air Handlers Delivers Big Performance in a Small Footprint

Option allows specifiers to choose the perfect air handler size for a space while simultaneously boosting energy recovery performance.

Option allows specifiers to choose the perfect air handler size for a space while simultaneously boosting energy recovery performance.

(LENEXA, KAN., April 3, 2024) Systemair, a global Swedish ventilation company and leading manufacturer of commercial ventilation products, is adding the ECO Heat Exchanger as an option for its popular Geniox line of air handlers in North America. Previously only available in Europe, the new ECO Heat Exchanger allows designers and installers to choose an upsized heat recovery module without increasing the unit size—which means higher efficiencies at nearly the same square footage and with a lower pressure drop.

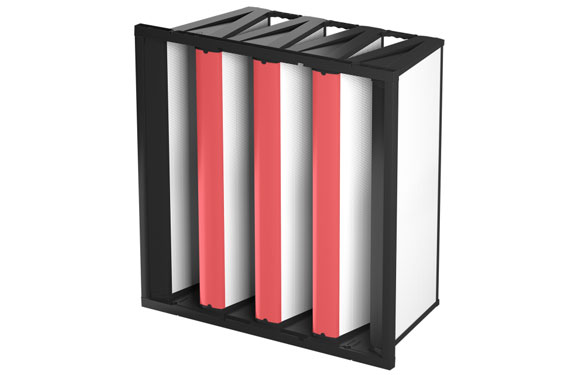

Geniox ECO maintains the core features of the Geniox air handling unit (including a versatile, modular platform with complete customization) while introducing a unique middle module, providing several additional advantages:

- Enhanced energy efficiency: Professionals now have the flexibility to select a larger heat recovery component, expanding fresh air exchange capacity, without altering the overall unit size. This feature is particularly useful when project specifications demand a specific CFM but require increased performance.

- Compact footprint, expanded capabilities: Despite its heightened heat recovery capabilities, the Geniox ECO ensures that the compact size of the air handling unit stays a priority. This is crucial for projects with space constraints, allowing for versatile integration into various building configurations.

- Cost savings at the core: With improved energy efficiency and the ability to customize heat recovery for specific project needs, the Geniox ECO Heat Exchanger contributes to an overall reduction in energy consumption. This translates into long-term cost savings for building owners, making the system not only environmentally friendly but also economically advantageous.

In addition to a larger heat recovery section, the Geniox ECO minimizes pressure drop across the unit; a lower pressure drop ensures efficient airflow maintenance, reducing the workload on fans and associated components. This optimization not only enhances overall system performance but also contributes to energy savings by demanding less power for air movement.

The achievement of lower pressure drop aligns seamlessly with broader goals of energy conservation and sustainability. The Geniox ECO not only optimizes heat recovery but also minimizes the energy needed for air circulation. This dual focus on efficiency and reduced energy consumption supports green building initiatives and promotes environmentally responsible HVAC practices.

“The Geniox ECO Heat Exchanger stands as a testament to Systemair’s commitment to advancing HVAC solutions, providing professionals with a unified platform that harmonizes energy efficiency, cost-effectiveness, and environmental sustainability,” said Jared Smith, Regional Technology and Product Director for Systemair North America. “Combined with the Geniox line’s highly customizable, modular platform, this addition further enhances the air handler’s versatility and ability to meet the needs of a project’s unique design parameters, challenges, and budget.”

The World’s Most Flexible AHU Platform

The Geniox air handling unit range comes with multiple product lines to suit different applications and use cases. The flexible, modular platform allows for complete customization of heat and energy recovery, cooling, filtration, mixing, and other elements according to each individual project.

In addition, Geniox units feature thermally insulated double-wall construction and ABS-designed corners to minimize heat loss and eliminate thermal bridging; various roof options, including a factory-installed roof with double-sloped A-frame design, rain shield protection, and snow load support; vertical supply or return access points; service windows for easy inspection; and lockable handles. Geniox units are #HygienicByDesign, constructed using smooth surfaces that are easy to clean and resistant to corrosion.

Along with new-construction applications, Geniox units can be broken down into smaller sections horizontally as well as vertically, providing opportunities for retrofit projects where space constraints and/or tight entryways are an issue.

For full details, visit http://www.systemair.net.