Products

APJeT Achieves 99.9999% Kill Rates of Surrogate Human Coronavirus with New Air Plasma Technology

As the pandemic surges, APJeT®, Inc., an advanced technology company located in Research Triangle Park, Morrisville, NC, today announced the completion of system prototypes for the commercial use of atmospheric plasma in disinfecting bacteria and viruses in air and on surfaces to reduce the spread of COVID-19. APJeT’s team of scientists and engineers, the first to develop the capability to stabilize atmospheric plasma in a very dense, high-powered form, has now built systems that kill microbes on surfaces (such as floors and bedrails), on packages, and in the air when integrated into HVAC systems or stand-alone air purifiers.

APJeT also released independent laboratory test results on the disinfection capabilities, or ‘kill rates’, of its new virus disinfection technology, which surpass alternative solutions like UV(C) light.

APJeT also released independent laboratory test results on the disinfection capabilities, or ‘kill rates’, of its new virus disinfection technology, which surpass alternative solutions like UV(C) light.

In testing surface disinfection, APJeT’s plasma surface disinfection ‘wand’ has shown a 99.9999% (6-log) kill rate on a human coronavirus (a COVID-19 surrogate) when applied for 90 seconds. By comparison, data on UV(C) light from the International Ultraviolet Association website claims a 99.9 % (3-log) kill rate of a coronavirus (not COVID-19). APJeT’s wand testing was conducted and certified by ResInnova Laboratories, an independent, IAC certified laboratory in Maryland that specializes in microbial testing for health care applications.

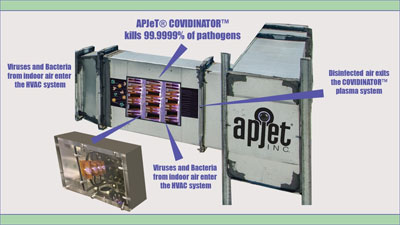

APJeT’s plasma air disinfection device, the ‘COVIDINATOR™, was tested by EMSL Analytical, a leading US environmental testing firm. Certified results confirm a complete elimination, or ‘total kill’, in one pass of room-circulated air. EMSL tested air disinfection rates using Staphylococcus Epidermidis as a surrogate bacteria for MRSA, which is listed on the EPA’s website as being more difficult to eliminate than coronaviruses.

“The outside testing of APJeT’s new, cold plasma technology for circulated air and surface disinfection confirms our in-house results. Reducing airborne virus spread indoors is perhaps the biggest challenge in fighting the pandemic. We now know that we can apply plasma disinfection to air as it passes through the HVAC systems of offices, schools, hospitals and airplanes killing the airborne viruses that wearing masks and physical distancing don’t fully protect us from,” says APJeT CEO, Bentley Park.

Atmospheric plasma is a $1.4 billion industry. The technology is used across several manufacturing processes; including automotive, textiles and medical devices; to disrupt a material’s surface at the molecular level for cleaning and increased adhesion characteristics.

APJeT’s plasma disinfection devices use a patent-pending cold plasma technology that breaks down the oxygen (O2) and nitrogen (N2) molecules in air into individual atoms. When these atoms recombine with the moisture in air, they create what are known as ‘reactive species’, which are highly effective in killing viruses, bacteria and fungi.

APJeT has developed four hardware prototypes for the application of its plasma disinfection technology: A ‘wand’ for treating surfaces, a ‘kill box’ (the COVIDINATOR™) for article disinfection, an air disinfection device for integration into existing and new HVAC systems, and a stand-alone air purifier.

APJeT expects that its air and surface disinfection technology will be widely used in hospitals, offices, and schools and in the airline, cruise, and hotel industries, which have been among the hardest hit by the current pandemic. APJeT’s patented air disinfection system and design can be easily incorporated into existing and new HVAC systems in community spaces, large and small, effectively disinfecting the air as it flows through those systems. The surface disinfection devices have applications throughout the supply chain.

“The other good news,” according to Park, “is that plasma disinfection has been shown to be more effective and safer than UV(C) light disinfection and without the toxicity to humans of common cleaning chemicals. APJeT disinfection can be used daily to reduce the spread of COVID-19 and to help prevent new epidemics or pandemics.”

VIDEO: How it Works: APJeT Air and Surface Disinfection

About APJeT

APJeT®, Inc., an advanced technology company, began as a lab-based entity at Los Alamos National Laboratory in Santa Fe, New Mexico. The company transitioned to North Carolina State University in 2009, where it was the first to develop the capability to stabilize atmospheric plasma in a very dense, high-powered form. Today, APJeT is located in the Research Triangle Park in Morrisville, NC and has developed proprietary atmospheric plasma technology and applications. APJeT has historically utilized this technology for the polymerization of monomeric coatings on materials in the textile industry.

Recently, the company and its scientists have expanded its plasma applications to address the need for disinfecting air and surfaces to reduce the spread of COVID-19 and help prevent future pandemics. Independent testing has shown 99.9999% (6-log) ‘kill rates’ for APJeT’s air and surface disinfection technologies. APJeT has developed four hardware prototypes for the application of its plasma disinfection technology: A ‘wand’ for treating surfaces, a ‘kill box’ (the COVIDINATOR™) for article disinfection, an air disinfection device for integration into existing and new HVAC systems, and a stand-alone air purifier. APJeT expects that its air and surface disinfection technology will be widely used in hospitals, offices, and schools and in the airline, cruise, and hotel industries, which have been among the hardest hit by the current pandemic.

Learn more about APJeT® at www.apjet.com.

To follow: Twitter – @Apjetinc. Facebook – https://www.facebook.com/ApjetInc. LinkedIn – https://www.linkedin.com/company/apjet-inc./