News

How Autonomous Robots Can Simplify HVAC Manufacturing and Refurbishment

By Robert Ravensbergen

Within the community of HVAC installers, manufacturers and contractors, configuration is always a challenge. System design, planning, installation and monitoring are all crucial, while sourcing or refurbishing can be accelerated, plotting any degree of customization for heavy expensive units is never easy.

This is primarily because HVAC manufacturing qualifies as “high-mix, low-volume.” This means that HVAC manufacturers produce units in “small” batches – typically less than 1000, but far less than the automotive or consumer electronics industry where automation has a deep beachhead.

This creates a challenge that comes with any part variation. The frequent changeover seen in high-mix industries means that use of most automation system requires programing and jigging or specialized materials handling for each new part type. His has been a particular challenge for robotics in particular, leaving their efficiency and productivity off limits. Fortunately, autonomous robots can change that.

What Are Autonomous Robots?

Autonomous robots are any robot that can program themselves. This is more commonly understood as “autonomous mobile robots,” which use localization, planning and manipulation methodologies in order to interpret and interact with an enclosed environment. The open-world version of this is, of course, self-driving cars, but door-to-door delivery robots and other comparable solutions are coming online to gradually make this kind of technology a fact of everyday life.

In industrial circumstances, however, these types of robots are generally limited to materials handling and inspection tasks. This doesn’t mean that that’s all autonomous robots as a whole are good for. Autonomous robots for value-added processes can use process constraints, know-how and goal-based instructions to generate a unique robot motion and tool path for each part in real process time.

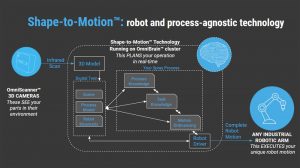

How does this work? A “see-plan-execute” framework is used. Using peripheral hardware, a robot can see or perceive parts in front of them to understand their shape or relate instructions to what they’re presented. Then, with adequate processing power at its disposal, plans can be made around instructions, process constraints and algorithms that enable the most efficient motion to be generated. Finally, with the right AI-based software, any existing industrial robot can be empowered to achieve this process as long as the planning system can relate its goals to the robot’s motion drivers.

What Can Autonomous Robots Do Today?

The concept of autonomous robots can apply to any value-added process, from welding to machining, spray processes, contact finishing, coating and even assembly in certain circumstances. Today, Omnirobotic offers Shape-to-Motion™ Technology, which currently supports spray process but is expected to support new processes in the future.

What goes into a spray process? A few things – the shape and curvature, indentation or surface features of the object. The nature and behavior of the spray process application, whether it’s a coating like paint or powder, or an abrasive spray like sandblasting or shot peening. The unique constraints of a spray material, like drip risks for paint or faraday caging for powder. Also, the tool control, timing, aperture and pressure of application (like PSI in a paint gun) needed to achieve a consistent coating or application over the entire surface of the object.

There is obviously a lot more to it, but what matters is that when the constraint of programming and jigging is removed from a robotic environment, a robot can be used for almost anything in any order, all the way down to a batch size of one. For the unique coating and consistency challenges that come to HVAC – particularly as applied to thermal protective coatings – this kind of tool set can offer a far higher degree of flexibility and efficiency than relying exclusively on skilled labor that is more scarce or sometimes simply not as consistent or fast moving.

How HVAC Suppliers Can Take Advantage

In HVAC manufacturing and installation, coating processes and customization depending on job site requirements can be unnecessarily time-consuming task. If you already have too much to do, automating tedious processes is the best place to start looking for how autonomous robots can be used. With that in mind, understanding the key bottlenecks – no matter part variation – and identifying what can be done to alleviate that blockage is the best first step in knowing which autonomous robot you’re ready for.

Ultimately, a day will come when these tools are commonplace. As demographic transition and skilled labor scarcity continue, robots will become ubiquitous for tasks that even skilled workers once enjoyed because there is simply not enough “human bandwidth” to do them. Further into the future, other machines and whole factories will be able to use autonomous solutions while relying on limited human oversight, ushering in a new era of autonomous manufacturing.

About the Author

Robert Ravensbergen is the Marketing Director at Omnirobotic, the only provider of autonomous robotics technology for industrial spray processes. You can reach Omnirobotic at sales@omnirobotic.com or visit https://omnirobotic.com/.