News

Supporting a Healthy Indoor Environment is a Trend That Should Stick Around

The importance of proper cleaning and disinfection has undoubtedly been vital for nearly every company, facility, and organization this past year. While the heightened awareness may eventually decline, it’s likely that many people will still look to companies to take the proper steps to support a healthy indoor environment and reduce the risk of bacterial or viral outbreaks.

“Many industries—such as food production and health care—had a strong focus on cleaning and sanitation before the pandemic, but that’s expanding to other industries where customers or occupants want to ensure they are entering a clean environment,” said Tim Kane, president of Goodway Technologies. “Some facilities already have regulations and oversight in place, but everyone needs to take the responsibility to put the proper protection in place.”

Goodway Technologies is offering best practices and tips for understanding what is needed to implement an effective cleaning and disinfection plan.

Identify the Level of Protection Needed

It’s essential to understand the level of protection required for a facility or building because there are differences between cleaning, sanitizing, and disinfection.

- Cleaning: Works by removing dirt and debris from surfaces through handwashing or mechanical cleaning processes.

- Sanitizing: Reduces the number of germs and bacteria on surfaces and objects to a safe level, as judged by public health standards or requirements.

- Disinfection: Disinfecting destroys or inactivates the bacteria and viruses that are clearly identified on a chemical product label when used on hard, non-porous surfaces. Other means, such as steam, can also destroy or inactivate bacteria and viruses.

Water-Based vs. Alcohol-Based

Various surface sanitation and disinfection solutions are available, and some solutions are more appropriate for a specific market or industry.

- Water-based sanitizers and disinfectants work best for general disinfection needs when surfaces can remain wet for up to 10 minutes. For less time-sensitive applications, water-based solutions may be a better fit and offer longer “kill” claim times. These require surfaces to remain wet for a more extended time but are generally more affordable solutions.

- Alcohol-based sanitizers and disinfectants are best for sensitive areas, such as electronics and high-touch areas, where quick drying is required. Spaces that require quick turnover, such as in the health care environment, will appreciate the benefit of a fast-drying time. The alcohol-based solutions are generally safe for sensitive electronics, making it an excellent solution for scales, machinery, computers, kiosks, and much more.

Overall Indoor Air Quality

Surface areas throughout a facility aren’t the only thing that needs to be considered when creating a healthy indoor environment. Indoor air quality is also an essential piece of minimizing the spread of infectious diseases or other harmful pollutants traveling throughout the airflow. The quality of the air inside can also impact an employee’s health. The Occupational Safety & Health Administration (OSHA) states that “poor indoor air quality can cause headaches, fatigue, concentration problems, skin rashes, and eye, nose, throat and lung irritation.”

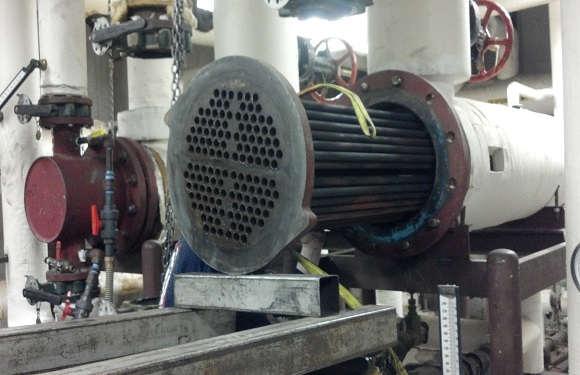

Heating and cooling systems are recognized as common sources of indoor air pollution, so routine maintenance and equipment cleaning is necessary. Ensuring your heating and cooling system is working effectively will help reduce the chances of poor indoor air quality impacting the occupants in a facility.

Additionally, portable air filtration systems utilizing true HEPA filtration technologies can increase localized air quality by significant factors. Consider adding portable air cleaning systems to high-traffic areas, like conference rooms, waiting rooms, break rooms, and more.

Visit the website to learn more about Goodway’s full line of sanitation and disinfection systems, or call 1-800-333-7467. You can also view the Sanitation and Disinfection Solutions catalog.

About Goodway Technologies

Founded in 1966, Goodway Technologies has been delivering better maintenance solutions for more than 50 years. Goodway Technologies provides innovative maintenance solutions for a wide variety of industries including commercial HVAC, food and beverage processing, power generation and manufacturing. Over the decades, Goodway has worked with our customers to create better solutions for tube cleaning systems, industrial vacuums, cooling tower maintenance systems, dry steam solutions, descaling systems, coil cleaning products and practically everything else for the care and maintenance of HVAC systems. Further information is available at www.goodway.com. Goodway is recognized as an ISO 9001:2015 certified company.