Air Movement

Ruskin Introduces BTD830 Damper for Low-Leakage Industrial Applications

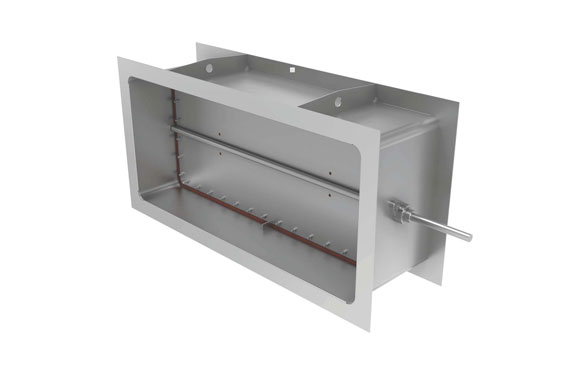

Grandview, MO – April 9, 2024 – Ruskin® announces the BTD830 bubble tight isolation damper, the company’s newest addition to its bubble tight product series. The BTD830 is a rectangular bubble tight damper ideal for applications where extremely low leakage is required. The rectangular design offers more free area, lower pressure drops, better airflow compared to round or oval dampers, and is a lower-cost alternative to other bubble tight dampers.

Typical applications include biotech labs, food processing operations, industrial process systems, laboratories and nuclear power plants, along with medical, military and pharmaceutical facilities.

The BTD830 is bubble tight according to the AMCA 500-D standard with a maximum velocity of 4,000 FPM, a static pressure of 10.0″ w.g. (2.5 kPa) and a temperature range of -40°F to 250°F (-40°C to 121°C).

Damper sizes range from 6″ x 6″ (15.2cm x 15.2cm) to 36″ x 16″ (91.4cm x 40.6cm). The flanged dampers can be mounted for horizontal or vertical airflow, and standard or custom mounting hole configurations are available.

Standard features include:

- Rectangular flanges

- Painted steel channel frame and blade

- Center-pivoted, double-skin blade with 12ga minimum thickness welded to a full-length axle

- Stainless steel sleeve bearings bolted to the damper frame

- Axle seal integrated with the bearing assembly

- Field replaceable solid silicone blade seal that is mechanically fastened to the blade

- Polyamide epoxy finish

Optional features include square flanges, a mil-spec frame or blade (304SS, 304LSS, 316SS, 316LSS) and mil-spec axle (316 SS, 316L SS) or finish (304SS, 304L SS, 316SS, 316L SS).

Ruskin can supply and mount actuators and limit switches as needed, including:

- Manual worm gear with handwheel

- Direct-mount, commercial grade

- Electric, quarter-turn rotary (fail in place, battery backup, spring return – 24V, 120V, 230V)

- Pneumatic, quarter-turn rotary (double acting or spring return)

Each BTD830 damper is fully cycled and tested at the factory prior to shipment in accordance with AMCA Standard 500-D. Ruskin performs bubble leak testing to 10.0″ w.g. (2.5 kPa) before shipment to ensure leakage performance. See the product data spec sheet for pressure drop information, per the AMCA 500-D-18 test standard.

The BTD830 is manufactured in an ISO9001 certified factory and comes with a 5-year limited warranty.

For more information about Ruskin, visit www.ruskin.com.

About Ruskin

Ruskin is a worldwide leader in manufacturing air control solutions. Backed by over 65 years of expert engineering and innovation, Ruskin is widely recognized as the most specified brand for high-performance air control solutions, including dampers, louvers, energy recovery ventilators (ERV), air measurement devices and sound control for HVAC systems. Ruskin products are used in commercial applications such as data centers, high-rise buildings, retail, hotels, healthcare and education facilities. In addition, Ruskin products can be found throughout the world’s industrial applications, such as warehouses and transportation hubs. Ruskin is part of the Johnson Controls group, which includes air systems, building automation and controls, fire detection, fire suppression, HVAC equipment, industrial refrigeration, retail solutions and security. For more information about Ruskin, visit www.ruskin.com, or find the company on Facebook, Twitter, LinkedIn and YouTube.

About Johnson Controls

At Johnson Controls (NYSE:JCI), we transform the environments where people live, work, learn and play. As the global leader in smart, healthy and sustainable buildings, our mission is to reimagine the performance of buildings to serve people, places and the planet.

Building on a proud history of nearly 140 years of innovation, we deliver the blueprint of the future for industries such as healthcare, schools, data centers, airports, stadiums, manufacturing and beyond through OpenBlue, our comprehensive digital offering.

Today, with a global team of 100,000 experts in more than 150 countries, Johnson Controls offers the world`s largest portfolio of building technology and software as well as service solutions from some of the most trusted names in the industry. Visit www.johnsoncontrols.com for more information and follow @JohnsonControls on social platforms.